News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

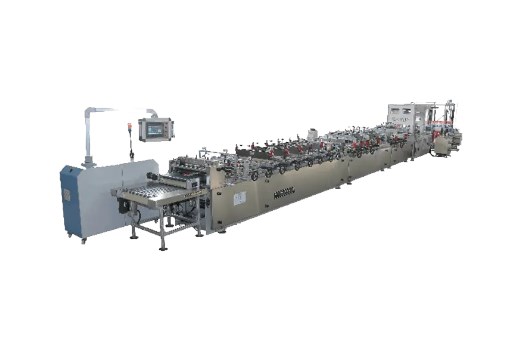

Intelligent Liner Bag Making Machine: A Revolution in the Industry

Industry Background of Intelligent Liner Bag Making Machines

With the rapid development of the packaging industry, traditional bag-making equipment can no longer meet modern enterprises' demands for high efficiency, precision, and automation. Especially in the food, chemical, and pharmaceutical industries, the production of liner bags requires not only uniform and aesthetically pleasing bags but also emphasizes sealing and stability. Intelligent Liner Bag Making Machine, as a new generation of intelligent equipment, with its high degree of automation and precise control, is gradually replacing traditional machinery and becoming a key tool for improving production efficiency and product quality.

In the global packaging equipment market, the trend toward intelligent automation is increasingly evident. Manufacturers focus not only on equipment speed but also on automated control systems, sensing technologies, and data management capabilities. The emergence of intelligent liner bag making machines meets the industry's dual demands for high precision and stability while reducing labor costs and operational complexity.

Core Technologies of Intelligent Liner Bag Making Machines

The greatest advantage of intelligent liner bag making machines lies in their technological integration capabilities. Advanced automatic control systems can monitor every stage of bag formation in real time—from material feeding and cutting to sealing—with precise regulation. Through a PLC control system combined with a human-machine interface, operators can easily adjust equipment parameters, enabling rapid switching between different bag specifications.

Furthermore, sensing technologies play a core role in intelligent liner bag equipment. Photoelectric sensors, pressure sensors, and other components can monitor material thickness, bag position, and sealing quality in real time, ensuring each finished bag meets standard requirements. The equipment can also record key production metrics through data acquisition systems, enabling traceable production management.

Enhancing Production Efficiency and Reducing Costs

Intelligent liner bag making machines not only focus on product quality but also greatly improve production efficiency. Compared to traditional equipment, their continuous production capability is stronger, reducing downtime and material waste. At the same time, the automated production process reduces reliance on manual labor, lowering labor costs and human errors.

By adopting intelligent liner bag machines, enterprises can also achieve flexible production management. With the equipment's software system, production lines can quickly switch between different bag types and specifications to meet diverse market demands. This high flexibility in production significantly enhances a company's responsiveness in a competitive market.

Integration of Environmental and Sustainability Concepts

With the increasing global focus on environmental protection, packaging companies have higher requirements for energy efficiency and environmental performance of equipment. Intelligent Liner Bag Making Machines are designed with energy conservation in mind, optimizing motor efficiency and minimizing energy consumption to achieve low-carbon production. Additionally, these machines are compatible with biodegradable or eco-friendly materials, meeting the trend toward green packaging.

Modern intelligent liner bag machines also support automatic waste recycling and reuse, reducing production waste. This not only aligns with environmental policies but also helps enterprises lower raw material costs, achieving sustainable development strategies.

Industry Applications and Market Prospects

Intelligent liner bag making machines have broad applications in food packaging, chemical products, pharmaceuticals, and industrial components. In the food industry, high-precision bag sealing and stable sealing ensure food safety. In chemical and pharmaceutical fields, the machines produce corrosion-resistant and high-temperature-resistant liner bags, ensuring product quality and storage safety.

In the future, with the development of smart manufacturing and Industry 4.0, intelligent liner bag machines will further integrate with the Internet of Things, big data, and artificial intelligence to achieve fully automated process management and remote monitoring. This not only improves production transparency but also offers enterprises more opportunities for value-added services.

Conclusion: Intelligence is the Future of Liner Bag Production

In summary, Intelligent Liner Bag Making Machine is not just a production tool but a critical technological force driving the upgrade of the packaging industry. By combining intelligent control, precise sensing, and data management, it enables efficient, accurate, and energy-saving production, meeting modern enterprises' pursuit of high quality and high efficiency. As the industry increasingly values intelligent manufacturing and green production, intelligent liner bag making machines will become essential for enterprises to enhance competitiveness and represent the inevitable trend of future liner bag market development.

RELATED PRODUCTS

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

English

English 中文简体

中文简体 русский

русский Español

Español