News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

Intelligent Bag Making Machine: Leading a New Era of Intelligent Packaging Manufacturing

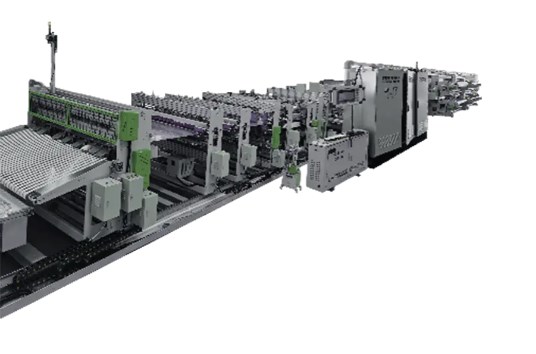

In the modern packaging manufacturing industry, the widespread adoption of intelligent equipment is driving efficiency innovation and quality improvements across the industry. As a crucial component of intelligent manufacturing, intelligent bag making machines have become core equipment in a variety of fields, including plastic packaging, paper packaging, and biodegradable and eco-friendly packaging. With the deepening integration of industrial automation, artificial intelligence, and the Internet of Things (IoT), intelligent bag making machines not only improve production efficiency but also represent a key direction for the packaging industry's move toward digitalization, flexibility, and green production.

I. Technological Innovation and Development Trends of Intelligent Bag Making Machines

The development of intelligent bag making machines has evolved from mechanization to automation to intelligence. Early bag-making equipment relied on mechanical structures to perform basic sealing, cutting, and forming functions. With the introduction of electronic control systems and servo drive technology, both speed and accuracy have been improved. Currently, the application of artificial intelligence algorithms, visual inspection systems, and IoT monitoring platforms has enabled bag making machines to achieve a higher level of intelligent decision-making and autonomous adjustment capabilities.

Intelligent bag-making machines can automatically identify and adjust production parameters based on different materials, thicknesses, and bag shapes. This enables high-precision positioning, automatic deviation correction, and constant temperature control, ensuring finished bags are precisely sized, securely sealed, and have a smooth appearance. Some high-end models also feature real-time monitoring and remote diagnostics, allowing operators to fully manage production status through a digital interface or cloud-based system. This significantly improves the bag-making machine's operational efficiency and ease of maintenance.

II. Core Advantages of Intelligent Control Systems

The intelligent control system is a critical component of the intelligent bag-making machine's operational system. Through the integrated application of PLC control, touchscreen operation, servo drive systems, and sensor networks, it digitizes and automates the entire bag-making process. The system collects parameters such as temperature, pressure, and speed in real time, and automatically adjusts operating conditions through algorithmic optimization to maintain optimal operating conditions.

Compared to traditional bag-making machines, intelligent bag-making machines offer significant improvements in energy consumption, production stability, and scrap rates. The system automatically issues alarms and corrects operations when abnormal fluctuations occur, avoiding production interruptions and material waste. Furthermore, intelligent control supports multi-process conversion and multi-bag type switching, making production more flexible and meeting the personalized needs of different customers and markets.

III. The Application Value of Intelligent Bag-Making Machines in the Packaging Industry Chain

Intelligent bag-making machines play a vital role in the modern packaging industry. Their applications span food packaging, pharmaceutical packaging, daily chemical product packaging, anti-static packaging for electronic products, and biodegradable and environmentally friendly packaging, among other areas. Driven by consumer upgrades and environmental trends, market demands for packaging bags' design, functionality, and sustainability are continuously increasing. Intelligent bag-making machines are crucial technical equipment for meeting these new demands.

Through intelligent, precise control, bag-making machines produce high-quality, highly consistent finished bags, improving the sealing and aesthetics of the packaging while extending the shelf life of the contents. Furthermore, the equipment supports the processing of new environmentally friendly materials such as multi-layer co-extruded films, PLA, and PBAT, enabling companies to achieve efficient production while also embracing the development of green manufacturing.

Intelligent bag-making machines are integrated with automatic printing, slitting, and laminating equipment to achieve fully automated production from raw material intake to finished packaging. This systematic solution reduces labor costs for packaging companies, improves production line flexibility and responsiveness, and creates a more competitive smart manufacturing system.

IV. Deep Integration of Artificial Intelligence and IoT Technologies

The intelligence of smart bag-making machines lies not only in their automated control but also in the deep integration of AI and IoT. By analyzing production data through AI algorithms, the equipment can automatically identify production anomalies and provide early warnings, enabling predictive maintenance and reducing downtime. Cloud-based systems enable managers to remotely monitor equipment operating status and achieve collaborative management across multiple factories.

The introduction of IoT technology has made smart bag-making machines the ultimate node for data collection and analysis. All production information can be aggregated and analyzed on a cloud platform, providing companies with a basis for decision-making on energy optimization, quality traceability, and production scheduling. This data-driven management approach not only improves production transparency but also accelerates the transformation of companies into smart factories.

As a significant innovation in the packaging manufacturing industry, smart bag-making machines are leading the industry towards efficiency, precision, and environmental friendliness. By integrating intelligent control systems, AI data analysis, and IoT technologies, they not only improve production efficiency and product quality but also provide solid support for companies to achieve intelligent production. In the future, with the growth of global packaging market demand and the continuous upgrading of technology, intelligent bag making machines will continue to play a key role in driving the packaging industry towards a new stage of greater intelligence and sustainability.

RELATED PRODUCTS

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

English

English 中文简体

中文简体 русский

русский Español

Español