News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

What Significant Cost Savings Can Intelligent Industrial Packaging Bag Making Machines Bring to Businesses?

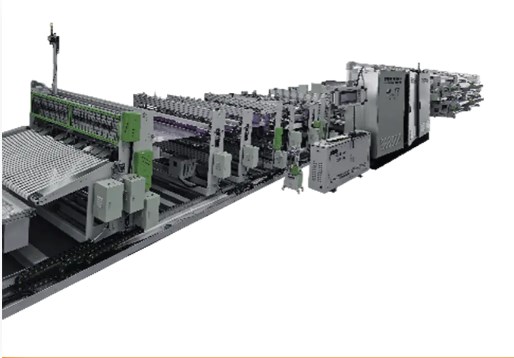

In modern industrial production, the quality of packaging materials and production efficiency directly impact a company's competitiveness and market performance. Intelligent Industrial Packaging Bag Making Machines, as highly efficient automated equipment, play a crucial role in optimizing production processes, improving product quality, and reducing costs. With continuous technological advancements, these machines can not only meet diverse production needs but also achieve intelligent management, further boosting productivity.

What is an intelligent industrial packaging bag making machine?

An intelligent industrial packaging bag making machine is a high-end device that combines automation technology and information technology, primarily used for producing various types of packaging bags. Unlike traditional packaging bag production equipment, intelligent packaging machines are designed to improve production efficiency, reduce manual intervention, and optimize the entire production process through intelligent control systems. Through advanced sensors, automated operating systems, and artificial intelligence algorithms, the machine can self-regulate and automatically monitor production status, maximizing productivity and minimizing production failures.

Increased Production Efficiency: The Perfect Combination of Automation and Intelligence

Traditional packaging bag production processes require a large amount of manual operation and adjustment, but the introduction of intelligent industrial packaging bag making machines has changed this. Through highly integrated automation systems, every step in the production line can be completed automatically, from raw material feeding to finished packaging bag output. The entire process requires almost no manual intervention, greatly improving production efficiency.

Intelligent equipment can also monitor the operating status of the production line in real time, automatically identify and correct machine faults, ensuring the continuity and stability of the production process. When the equipment malfunctions, the system will immediately alarm and provide fault diagnosis, helping operators quickly locate and resolve the problem. This highly automated production model not only reduces downtime but also significantly lowers labor costs.

Precise Control: Ensuring Perfection in Every Detail

Another major advantage of intelligent industrial packaging bag making machines is their precise control capabilities. From material cutting, printing, and sealing to forming, every step can be adjusted in real time through a high-precision control system, ensuring that the size, quality, and appearance of each packaging bag meet the requirements. Advanced sensors and laser alignment systems can accurately measure the thickness and width of the material, ensuring consistency in all aspects of the produced packaging bags.

This high-precision control not only improves product quality but also reduces waste caused by production errors. Through intelligent adjustment, the production line can adjust production parameters in real time according to actual conditions, avoiding errors that may arise from manual adjustments, ensuring that every bag of product meets the required standards.

Multifunctionality: Meeting Diverse Packaging Needs

Intelligent industrial packaging bag production machines are not limited to producing a single type of packaging bag. Their multifunctionality allows companies to adjust flexibly according to market demands. These machines can adapt to production requirements for different materials, sizes, and designs. Whether it's traditional plastic packaging bags or composite material packaging bags requiring high strength or special functions, intelligent equipment can easily handle them.

The high adaptability of intelligent equipment is also reflected in its ability to adapt to different production environments. Even in complex working environments, the machine can maintain efficient and stable production, which is of great significance for improving the company's rapid response capabilities and production flexibility in the market.

Data-driven Management: Comprehensively Improving Production Management

Intelligent industrial packaging bag production machines are not just simple production tools; they also possess powerful data analysis and management capabilities. The equipment is equipped with advanced Internet of Things (IoT) technology, which can collect and transmit production data in real time, including important indicators such as production speed, equipment operating status, and production quality. Through the data analysis system, companies can monitor various parameters in the production process in real time, ensuring that every link of production meets the predetermined standards.

Through big data analysis, production companies can accurately pinpoint bottlenecks in the production process and improve efficiency by adjusting production strategies. The precise data collection and analysis provide companies with a comprehensive monitoring platform, greatly improving the scientific and intelligent level of production management.

Efficient Energy Management: Reducing Enterprise Operating Costs

Intelligent packaging bag production machines not only improve production efficiency but also play a positive role in energy saving and emission reduction. The equipment design fully considers energy consumption and operating costs, adopting advanced energy management technology to dynamically adjust energy consumption according to actual production needs, avoiding unnecessary waste.

Through efficient energy management, companies can not only reduce energy costs but also reduce the burden on the environment, meeting the needs of modern industry for green production. In addition, the high efficiency of intelligent equipment also reduces maintenance costs caused by excessive equipment operation, allowing companies to maintain lower overall costs in long-term operations.

FAQ

What are the main advantages of intelligent industrial packaging bag production machines?

The main advantages of intelligent industrial packaging bag production machines are improved production efficiency, guaranteed production accuracy, enhanced product quality, and reduced manual intervention and downtime through automation. Intelligent management systems can also monitor production status in real time, helping companies improve their production management levels.

Which industries are suitable for intelligent industrial packaging bag production machines?

Intelligent industrial packaging bag production machines are suitable for a variety of industries, especially in fields with high demands on packaging bag quality, such as food, cosmetics, pharmaceuticals, and daily consumer goods. Its multi-functionality and high adaptability allow it to meet various production needs.

Do intelligent devices require extensive maintenance?

Intelligent devices generally have high stability and relatively low maintenance frequency. Through automatic monitoring systems, the equipment can self-diagnose in real time and provide timely warnings of potential problems, avoiding production interruptions caused by equipment failures. The efficient management system of the equipment can reduce manual intervention while extending the service life of the equipment.

What is the cost of intelligent industrial packaging bag production machines?

Although the initial investment in intelligent industrial packaging bag production machines is higher, due to their efficient production capacity, low maintenance costs, and energy-saving effects, companies can recoup their investment in a relatively short period and achieve long-term cost savings. Therefore, the long-term return on investment for intelligent equipment is very significant.

RELATED PRODUCTS

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

English

English 中文简体

中文简体 русский

русский Español

Español