News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

The Unseen Power of Intelligent Plastic Bag Making Technology

I. Introduction

In an era defined by rapid technological advancement and an increasing global demand for efficiency and sustainability, the manufacturing landscape is undergoing a profound transformation. Traditional production methods, often characterized by manual labor, material waste, and inconsistent output, are giving way to smarter, more automated solutions. The plastic bag manufacturing industry, a sector critical to global commerce and daily life, has historically faced its own set of challenges, including the inherent difficulties in minimizing waste, optimizing labor, and ensuring uniform product quality.

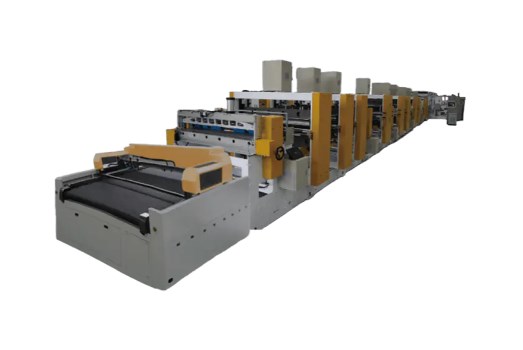

However, a new paradigm is emerging: the Intelligent Plastic Bag Making Machine. This isn't merely an upgraded piece of equipment; it represents a significant leap forward, integrating cutting-edge technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and advanced robotics. These intelligent machines are poised to revolutionize the industry by delivering unprecedented levels of automation, precision, and sustainability. This article will explore how these intelligent plastic bag making machines are reshaping the manufacturing process, paving the way for a more efficient, environmentally conscious, and productive future.

II. What is an Intelligent Plastic Bag Making Machine?

An Intelligent Plastic Bag Making Machine transcends the capabilities of conventional automated systems. It is defined by its ability to integrate and leverage sophisticated technologies to perform tasks with minimal human intervention, adapt to changing conditions, and optimize its own performance. At its core, it's a smart factory component designed for autonomous, high-precision manufacturing.

Key Components and Technologies:

- Sensors and Data Collection: These machines are equipped with an array of advanced sensors that continuously monitor critical parameters in real-time. This includes precise measurements of temperature during extrusion, pressure during sealing, material flow rates, and even the thickness and consistency of the plastic film. This constant stream of data forms the foundation for intelligent decision-making.

- Artificial Intelligence (AI) & Machine Learning (ML): The collected data is fed into powerful AI and ML algorithms, enabling the machine to:

- Predictive Maintenance: Analyze operational data to anticipate potential equipment failures before they occur, scheduling maintenance proactively and dramatically reducing unplanned downtime.

- Quality Control (Defect Detection): Utilize computer vision and pattern recognition to identify even minute defects in the plastic film or finished bags, ensuring only high-quality products proceed.

- Process Optimization: Continuously learn from production cycles to fine-tune parameters like extrusion speed, cutting force, and sealing temperature, optimizing material usage, energy consumption, and overall throughput.

- Adaptive Control: Automatically adjust settings to accommodate different material types (e.g., HDPE, LDPE, biodegradable polymers) and varying film thicknesses without manual recalibration.

- Internet of Things (IoT) Connectivity: IoT capabilities allow these machines to be seamlessly integrated into a broader digital ecosystem.

- Remote Monitoring and Control: Operators and managers can monitor machine performance, production status, and even control certain functions from anywhere, enhancing flexibility and responsiveness.

- Integration with Factory Management Systems (MES, ERP): Data from the intelligent machine can be directly fed into Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems, enabling holistic production planning, inventory management, and supply chain optimization.

- Data Sharing: Real-time data can be shared across the supply chain, improving transparency and facilitating just-in-time manufacturing.

- Robotics and Automation: Integrated robotic arms and automated systems handle repetitive and labor-intensive tasks with precision and speed.

- Automated Material Loading/Unloading: Robots can efficiently load raw material rolls and unload finished product stacks.

- Precision Cutting and Sealing: Robotic mechanisms ensure consistent and accurate cutting and sealing, minimizing variations.

- Automated Packaging and Stacking: Finished bags are automatically counted, packaged, and stacked, ready for shipment, further reducing manual handling.

- Advanced Control Systems: Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) provide robust and intuitive control over the machine's operations. Specialized software orchestrates the complex interplay between sensors, AI, robotics, and mechanical components, ensuring seamless and synchronized operation.

III. Advantages and Benefits

The adoption of intelligent plastic bag making machines brings a multitude of advantages that significantly impact efficiency, quality, cost, sustainability, and safety within the manufacturing process.

A. Increased Efficiency and Productivity:

| Benefit | Description |

|---|---|

| Higher Output Rates | With optimized processes, reduced human intervention, and continuous operation, intelligent machines can produce significantly more bags per hour compared to traditional setups. |

| Reduced Downtime | Predictive maintenance, enabled by AI, minimizes unexpected breakdowns, ensuring machines operate consistently with fewer interruptions. |

| Faster Changeovers | Automated adjustments and pre-programmed settings allow for quicker transitions between different bag sizes, types, or material specifications, maximizing operational time. |

B. Enhanced Quality and Consistency:

| Benefit | Description |

|---|---|

| Minimized Defects | Real-time monitoring and AI-driven adjustments detect and correct anomalies instantly, leading to a drastic reduction in defective products. |

| Uniform Bag Dimensions and Sealing Strength | The precision of robotics and advanced control systems ensures every bag meets exact specifications, from its dimensions to the strength of its seals, enhancing product reliability. |

C. Cost Reduction:

| Benefit | Description |

|---|---|

| Lower Labor Costs | Automation reduces the need for extensive manual labor, leading to significant savings on wages and associated overheads. |

| Reduced Material Waste | AI-driven optimization of material usage, coupled with precise cutting and sealing, minimizes scrap and raw material consumption. |

| Energy Savings | Intelligent process control ensures machines operate at optimal energy levels, reducing power consumption. |

| Decreased Maintenance Costs | Predictive maintenance shifts from reactive repairs to planned interventions, extending equipment lifespan and reducing emergency repair expenses. |

D. Improved Sustainability:

| Benefit | Description |

|---|---|

| Reduced Material Consumption | By minimizing waste and optimizing film usage, these machines contribute directly to a more resource-efficient production. |

| Lower Energy Footprint | Optimized operational parameters and efficient motor controls lead to reduced overall energy consumption, lessening the environmental impact. |

| Ability to Handle Recycled or Biodegradable Materials More Effectively | The adaptive control systems can better manage the unique properties of recycled or novel biodegradable polymers, facilitating their integration into the production cycle. |

| Less Scrap Generation | Fewer defects and optimized processes mean less material ending up as waste, supporting circular economy initiatives. |

E. Safety and Ergonomics:

| Benefit | Description |

|---|---|

| Reduced Human Intervention in Hazardous Areas | Automated loading, cutting, and stacking processes remove human operators from potentially dangerous machinery, significantly improving workplace safety. |

| Less Repetitive Strain for Workers | By taking over monotonous and physically demanding tasks, intelligent machines reduce the risk of repetitive strain injuries and improve overall ergonomics for the remaining workforce. |

IV. Applications and Impact

The transformative capabilities of intelligent plastic bag making machines extend across a wide array of industries, fundamentally reshaping production processes and workforce dynamics.

A. Diverse Industries:

- Retail and Packaging: The most obvious application, where high volumes of consistent, durable bags are required for shopping, product packaging, and promotional purposes.

- Food and Beverage: Critical for producing food-grade bags that meet stringent hygiene standards, often involving specialized films for freshness and extended shelf life.

- Medical and Pharmaceutical: Demands sterile, precise, and often tamper-evident packaging, which intelligent machines can deliver with high reliability.

- Agriculture: Used for packaging produce, fertilizers, and other agricultural products, often requiring robust and weather-resistant bags.

B. Case Studies/Examples (Hypothetical or General):

Consider a hypothetical scenario: A medium-sized packaging factory, struggling with high material waste and frequent machine breakdowns, invests in intelligent plastic bag making machines. Within a year, they report a 25% reduction in material waste due to AI-driven optimization and defect detection. Simultaneously, their production output increases by 30% as a result of reduced downtime and faster operational speeds. This not only boosts their profitability but also significantly improves their environmental footprint. Another example might be a company that previously required a team of ten operators for a production line now needing only two skilled technicians to oversee multiple intelligent machines, demonstrating a dramatic increase in labor efficiency.

C. Reshaping the Workforce:

The advent of intelligent machines doesn't necessarily eliminate jobs but rather redefines them. There is a clear shift from manual labor to skilled technicians and data analysts. Workers who once performed repetitive tasks are now needed to:

- Monitor machine performance and interpret data.

- Program and troubleshoot complex systems.

- Perform predictive maintenance and advanced repairs.

- Develop and refine AI algorithms for further optimization.

This necessitates a significant focus on retraining and upskilling the existing workforce to meet the demands of this new, technologically advanced manufacturing environment.

V. Challenges and Considerations

While the benefits of intelligent plastic bag making machines are compelling, their adoption is not without challenges that require careful consideration.

A. Initial Investment Cost:

The most significant hurdle for many manufacturers is the high upfront capital expenditure required to acquire these advanced machines. The integration of AI, IoT, robotics, and sophisticated control systems makes them considerably more expensive than traditional equipment. This can be a barrier for smaller businesses or those with limited access to capital.

B. Technical Expertise:

Operating, maintaining, and optimizing intelligent machines demands a workforce with specialized skills. There is a critical need for skilled personnel proficient in areas such as industrial automation, data science, network administration, and advanced robotics. Companies must invest in training programs or recruit new talent to bridge this knowledge gap.

C. Integration Complexity:

Connecting new intelligent machines with existing factory infrastructure, legacy systems, and diverse software platforms can be highly complex. Ensuring seamless data flow, communication protocols, and operational compatibility requires meticulous planning and often significant IT investment. This integration complexity can lead to unforeseen delays and costs.

D. Cybersecurity Risks:

As intelligent machines become increasingly connected via IoT, they also become potential targets for cyber threats. Protecting sensitive production data, proprietary algorithms, and control systems from malicious attacks, data breaches, or operational disruptions is paramount. Robust cybersecurity measures are essential to safeguard these interconnected systems.

E. Ethical Considerations:

The widespread adoption of automation inevitably raises ethical considerations, particularly concerning job displacement. While new roles are created, the transition can lead to a reduction in certain types of manual labor, necessitating proactive strategies for workforce retraining and social support. Manufacturers also bear the responsibility of ensuring that the implementation of these technologies is done in a way that benefits society broadly, not just corporate bottom lines.

VI. The Future of Plastic Bag Manufacturing

The trajectory of intelligent plastic bag manufacturing points towards an even more integrated, adaptive, and sustainable future, deeply embedded within the broader concept of Industry 4.0.

A. Further Integration of AI and Robotics:

Expect to see machines becoming even more autonomous, capable of self-diagnosis, self-correction, and even self-optimization with minimal human oversight. AI will drive more sophisticated predictive analytics, not just for maintenance but for market demand forecasting and dynamic production scheduling. Robotics will become more agile and collaborative, working alongside human operators in a seamless fashion.

B. Advanced Materials:

The machines of the future will be designed to handle an even wider array of advanced materials, including next-generation biodegradable, compostable, and truly circular polymers. This will involve more precise control over material properties and processing conditions to ensure optimal performance and environmental impact.

C. Customization and On-Demand Production:

Intelligent machines, with their rapid changeover capabilities and data-driven adaptability, will facilitate highly customized and on-demand production. This "agile manufacturing" will allow businesses to respond quickly to niche market demands, produce smaller batches efficiently, and offer greater product personalization.

D. Circular Economy Integration:

Future intelligent machines will be designed with the circular economy firmly in mind. This means not only optimizing for reduced waste during production but also potentially integrating systems for processing recycled content more effectively or even facilitating the collection and reprocessing of used bags within a closed-loop system. Their data insights could also inform better recycling infrastructure development.

E. Industry 4.0 and Smart Factories:

Intelligent plastic bag making machines are a core component of the larger vision of Industry 4.0 and smart factories. They will communicate seamlessly with other machines, supply chain partners, and enterprise systems, creating fully interconnected and self-optimizing production environments. This holistic approach promises unprecedented levels of efficiency, responsiveness, and sustainability across the entire manufacturing value chain.

VII. Conclusion

The intelligent plastic bag making machine stands as a testament to the transformative power of modern technology in manufacturing. By integrating AI, IoT, and advanced robotics, these machines are not merely automating tasks; they are fundamentally reshaping the industry. They offer a compelling suite of benefits, including vastly increased efficiency, unparalleled quality and consistency, significant cost reductions, and a tangible improvement in environmental sustainability. While challenges such as initial investment, the need for specialized expertise, and cybersecurity risks must be addressed, the long-term advantages far outweigh these hurdles.

Looking ahead, the evolution of these intelligent machines will continue to push the boundaries of what's possible, driving further automation, enabling the use of more sustainable materials, and fostering highly agile and customized production models. Ultimately, the intelligent machine is not just about making bags; it's about shaping the future of manufacturing towards a smarter, greener, and more productive paradigm, demonstrating how innovation can lead to both economic prosperity and environmental stewardship.

RELATED PRODUCTS

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

English

English 中文简体

中文简体 русский

русский Español

Español