News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

Leading the Future with Intelligence: The Innovation and Reinvention of the Intelligent Food Bag Making Machine

Disrupting Tradition: The Rise of the Intelligent Food Bag Making Machine

Amidst the rapid development of modern industry, the food packaging industry is undergoing unprecedented transformation. Traditional food bag making methods, whether semi-automatic or fully automated, face challenges in efficiency, precision, and flexibility. However, with the deep integration of artificial intelligence, the Internet of Things, and precision machinery, the Intelligent Food Bag Making Machine has emerged. This represents more than just an upgrade; it represents a profound revolution in production methods.

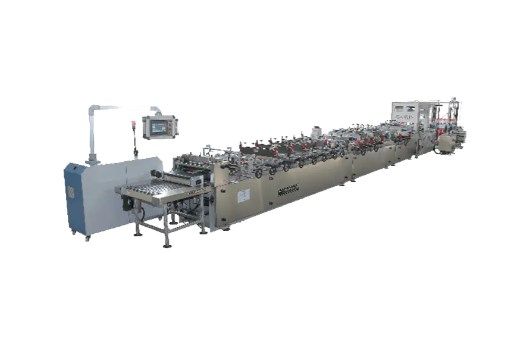

The Intelligent Food Bag Making Machine is a new generation of bag-making equipment that integrates advanced sensing, intelligent control, and automated execution systems. It breaks away from the monotonous, fixed operating model of traditional bag-making machines and can autonomously sense, analyze, and adjust production parameters to meet the needs of packaging of varying materials, sizes, and shapes. This transformative force is fundamentally changing the production logic of food companies, making efficiency, flexibility, and precision a reality.

Core Technology: The Source of the Intelligence of Intelligent Bag Making

The intelligence of the intelligent food bag making machine is not groundless; it is built on the support of multiple cutting-edge technologies. These core technologies together form its powerful brain and flexible limbs.

Vision and Sensing: The "Smart Eye" of Precise Identification

Traditional bag-making machines rely on mechanical limits and manual calibration to ensure bag size and printing position. Intelligent bag-making machines, on the other hand, incorporate high-resolution vision recognition systems. This system monitors the feeding of packaging materials, the alignment of printed patterns, and the sealing and cutting positions of bags in real time. Using advanced image processing algorithms, it instantly identifies any minor deviations and instructs the actuators to make millisecond-level adjustments. Various high-precision sensors, such as tension sensors, position encoders, and temperature sensors, also form the machine's sensor network, providing real-time, comprehensive data support to the central control system.

Algorithms and Control: The Adaptive "Brain"

The core of the intelligent bag-making machine is its built-in intelligent control system. This system goes beyond simple program logic and incorporates machine learning and artificial intelligence algorithms. It learns from historical production data to establish optimal production models for different materials, thicknesses, and speeds. When production conditions or material properties change, this system adaptively adjusts key parameters such as sealing temperature, pressure, cutter speed, and feed tension, ensuring that every bag meets the highest quality standards. This adaptive capability significantly reduces manual intervention and debugging time, improving production efficiency and product yield.

Flexible Manufacturing: A Powerful Tool for Meeting Individualized Needs

In the era of consumer upgrading, market demand for packaging is increasingly diverse. From simple stand-up pouches and three-side seal bags to complex custom-shaped bags and stand-up zipper bags, the variety is vast. Traditional bag-making machines often require mold changes or cumbersome mechanical adjustments to accommodate different bag shapes, which is not only time-consuming and labor-intensive, but also limits production flexibility.

The intelligent food bag-making machine, with its highly integrated modular design and digital control system, completely resolves this pain point. It can quickly switch between different bag-making modes via software commands. For example, to switch from standard three-side seal bags to stand-up zipper bags, simply select the corresponding preset program on the human-machine interface, and the machine will automatically adjust the mold, switch sealing parameters, and activate the zipper mechanism. This seamless switching capability enables companies to easily handle small-batch, high-variety orders, significantly improving market responsiveness and competitive advantage.

Production Efficiency and Sustainable Development: The Dual Benefits of Smart Bag Making

The application of smart food bag-making machines not only revolutionizes production models but also demonstrates significant benefits in terms of production efficiency and sustainable development.

In terms of production efficiency, thanks to their precise control and adaptive capabilities, smart bag-making machines can operate stably at higher speeds while significantly reducing scrap rates. They accurately calculate material usage, reducing scrap and thus saving raw material costs. The equipment's fault diagnosis system monitors operating status in real time, predicts potential mechanical failures, and issues early warnings, thereby reducing unplanned downtime and ensuring continuous and stable operation of the production line.

In terms of sustainable development, the smart bag-making machine optimizes the use of electrical energy through its efficient energy management system. It intelligently adjusts motor power and heating system temperature based on actual production load, avoiding unnecessary energy waste. Furthermore, with the increasing use of biodegradable and new environmentally friendly materials, intelligent bag-making machines, through their flexible parameter adjustment capabilities, can perfectly adapt to the characteristics of these new materials, providing strong technical support for the promotion of environmentally friendly packaging.

As a key component of intelligent manufacturing, intelligent food bag-making machines are reshaping the future of the food packaging industry with their unique "intelligence" and "flexibility." They not only bring higher efficiency and lower costs to businesses, but also provide consumers with safer, more aesthetically pleasing, and more personalized product packaging. This intelligent technology-driven bag-making revolution has only just begun, and its potential and impact are bound to continue to be far-reaching.

RELATED PRODUCTS

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

English

English 中文简体

中文简体 русский

русский Español

Español