News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

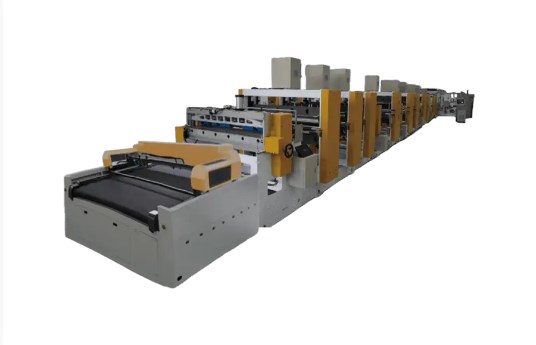

Intelligent Liner Bag Making Machine: Core Equipment Reshaping the Packaging Industry's Production Landscape

Amid the packaging industry's shift toward intelligent manufacturing, intelligent liner bag making machines are becoming a key piece of equipment for companies to enhance their core competitiveness. Compared to traditional bag-making equipment, this type of equipment, with its advantages of automation, precision, and intelligence, not only addresses the pain points of traditional production models, such as low efficiency, high waste, and inconsistent quality, but also meets the current packaging industry's demand for green production and flexible manufacturing, becoming a key force in driving the upgrading of the packaging industry chain.

Core Technical Advantages of the Intelligent Liner Bag Making Machine

The professionalism of the Intelligent Liner Bag Making Machine is first reflected in its integration of multiple cutting-edge technologies, enabling intelligent control throughout the entire production process. During fabric processing, the machine's intelligent tension control system automatically adjusts tension parameters based on the characteristics of different materials (such as PE, PP, and composite film), preventing problems such as wrinkles and stretching caused by uneven tension, thereby ensuring the fundamental quality of liner bags from the source. Furthermore, the intelligent feeding system uses high-precision sensors to monitor fabric conveying speed in real time, precisely linking with the subsequent bag-making process to ensure synchronization of each step and significantly reduce material loss during production. During the bag-making process, the intelligent liner bag making machine utilizes CNC cutting technology and a precision heat-sealing system, which distinguish it from traditional equipment. Powered by a high-performance processor, the CNC cutting system automatically adjusts the cutting path based on preset bag parameters (such as length, width, and opening), achieving millimeter-level cutting accuracy and effectively eliminating the errors that can occur with traditional manual sizing. The precision heat-sealing system, through intelligent coordinated control of temperature, pressure, and time, automatically matches the optimal heat-sealing parameters for fabrics of varying thicknesses and materials. This ensures a secure seal while preventing fabric burns and insufficient seal strength caused by improper heat-sealing parameters, further enhancing the quality of the liner bags.

The intelligent liner bag making machine's intelligence is also reflected in its data-driven management capabilities. The machine's equipped Industrial Internet of Things (IIoT) module collects key production data (such as production speed, pass rate, and material consumption) in real time and uploads this data to a cloud-based management platform. Through the platform, company managers can monitor production progress and analyze production data at any time, promptly identifying potential problems and making adjustments. This enables transparent, data-driven management of the entire production process, providing data support for optimizing production plans and reducing operating costs.

The Impact of Intelligent Liner Bag Making Machines on the Packaging Industry

As consumer demand for packaging product quality continues to rise and environmental protection policies increasingly restrict the packaging industry, intelligent liner bag making machines are bringing multi-dimensional changes to the packaging industry. In terms of quality improvement, the equipment's intelligent control throughout the entire process significantly reduces the impact of human factors on product quality, significantly improving key indicators such as dimensional consistency, sealing, and surface smoothness of liner bags. This meets the stringent packaging requirements of industries such as food, pharmaceuticals, and electronics, helping packaging companies expand into the high-end market.

In terms of green production, the efficiency and precision of intelligent liner bag making machines effectively reduce material loss and energy consumption during production. Furthermore, some equipment is compatible with biodegradable materials, enabling the production of biodegradable liner bags that meet environmental requirements, helping packaging companies respond to the national "dual carbon" policy and achieve green transformation. This green production capability not only enhances the company's social image but also makes it more competitive in a market environment characterized by increasingly stringent environmental regulations.

In terms of flexible manufacturing, the rapid changeover capabilities of intelligent liner bag making machines are a key advantage for packaging companies in responding to fluctuating market demands. Traditional bag-making equipment requires manual adjustment of multiple parameters, which is time-consuming. However, intelligent liner bag making machines, through digital control, can adjust and change bag parameters in a fraction of the time, enabling efficient production of a wide variety of small-batch orders. This flexible manufacturing capability enables packaging companies to respond more quickly to market demands, improving their market adaptability and customer satisfaction.

Market Trends of Intelligent Liner Bag Making Machines

From a market perspective, with the accelerated transformation of the packaging industry towards intelligent manufacturing and the growing demand for high-quality, environmentally friendly liner bags in downstream industries, the market demand for intelligent liner bag making machines is continuing to rise. This is particularly true in industries with high packaging quality requirements, such as food and pharmaceuticals, as well as the growing packaging demand driven by the e-commerce industry, providing ample market opportunities for intelligent liner bag making machines.

From a technological perspective, intelligent liner bag making machines will develop towards a higher level of intelligence and integration in the future. On the one hand, artificial intelligence technology will be further integrated into the equipment's control system, enabling the equipment to learn and optimize autonomously, automatically adjusting production parameters based on production data, achieving more efficient and precise production. On the other hand, the equipment will be more closely integrated with upstream and downstream production processes (such as raw material supply, finished product testing, warehousing and logistics), forming a complete intelligent production line, further improving the overall production efficiency of packaging companies.

As core equipment in the packaging industry's intelligent transformation, intelligent liner bag making machines not only possess significant technological advantages but also play a significant role in promoting quality improvement, green transformation, and flexible manufacturing in the packaging industry. In future market development, with continuous technological innovation and growing market demand, intelligent liner bag making machines will become key to enhancing the competitiveness of packaging companies, driving the entire packaging industry towards more efficient, environmentally friendly, and intelligent development.

RELATED PRODUCTS

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

English

English 中文简体

中文简体 русский

русский Español

Español