News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

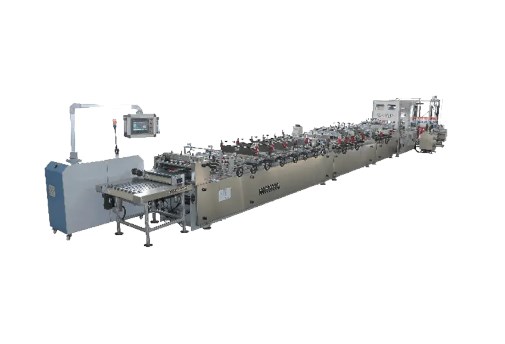

Intelligent Liner Bag Making Machine: Core Equipment Reshaping the Future of Packaging

Overview

In the global trend of accelerating the upgrading of manufacturing towards intelligence and automation, the Intelligent Liner Bag Making Machine, as a crucial technological equipment in the packaging field, is driving production method innovation with unprecedented efficiency and precision. For industries such as food, chemicals, pharmaceuticals, and electronics, the quality and production efficiency of inner liner bags directly impact transportation safety, product preservation, and enterprise cost control. Intelligent liner bag making machines are becoming key equipment for enterprises to succeed.

The industry value of intelligent bag making systems is rapidly being amplified

As production lines increasingly demand flexibility, stability, and traceability, traditional bag making methods can no longer meet the dual requirements of quality and efficiency. The Intelligent Liner Bag Making Machine, by integrating technologies such as automatic detection, precision control, intelligent compensation, and digital management, enables the entire bag making process to operate more stably and demonstrates significant advantages in material adaptability, bag type switching speed, welding quality, and energy consumption control. The system maintains excellent controllability while operating at high speed, ensuring consistent standards in sealing strength, dimensional accuracy, and surface flatness of the final products. This provides a fundamental support for brands to consistently deliver high-quality packaging.

Enhanced production experience through intelligence

Intelligent technology brings not only increased efficiency but also a higher-level production experience. Using this type of equipment, companies can significantly reduce their reliance on skilled operators, while minimizing downtime and adjustment time, making production plans more transparent and stable. The equipment is highly adaptable when processing films of different materials, automatically adjusting tension and temperature to maintain bag quality within the optimal range, providing strong technical support for complex production of multiple varieties and specifications.

Core production technology and future direction

Looking at the future direction of the industry from the perspective of core production technology, the core of the intelligent inner liner bag making machine is not simply automation, but a comprehensive capability built around control precision, sealing technology, vision systems, and data management. During operation, the machine continuously optimizes motion coordination and sealing curves by collecting data in real time and performing algorithmic judgments, ensuring stable sealing results for every seal. Material control at each stage—from conveying and folding to forming and sealing—is meticulously broken down and digitally managed, minimizing variations between batches.

Advances in sealing and vision inspection

Regarding sealing technology, the intelligent bag-making machine utilizes precise temperature control and pressure compensation to ensure uniform stress on the film in the heating zone, resulting in stronger and smoother welds, fundamentally improving bag durability and sealing performance. A vision inspection module analyzes bag shape, position, and alignment in real time, automatically correcting deviations to ensure a stable and controllable production process. The increasing use of multi-layer films and functional films in the packaging industry necessitates more precise control during processing, making intelligent bag-making systems an indispensable technological support.

Material adaptability and process control

Multi-layer and functional films require finer control across the entire process chain. The Intelligent Liner Bag Making Machine delivers precise management of tension, feed, alignment, and thermal profiles so that diverse materials can be processed with consistent quality. This technical depth allows manufacturers to expand product offerings without sacrificing production stability.

A more efficient production chain enhances enterprise competitiveness

The role of the Intelligent Liner Bag Making Machine in the production chain extends beyond bag making itself, encompassing its integration with the overall manufacturing process. With the increasing prevalence of automated factory design concepts, the compatibility and scalability of equipment with external systems are becoming increasingly important. Modern intelligent bag-making machines can interface with upstream film roll conveying systems, online printing systems, and downstream packaging, boxing, and logistics information systems to enable continuous operation of the entire production line.

Data as a management asset

Data recorded by the system during production, such as temperature, speed, energy consumption, and waste ratio, can be transformed into management assets for the factory. Through backend analysis, equipment maintenance nodes can be predicted, allowing companies to move away from traditional experience-based maintenance methods and towards more scientific equipment management decisions. Production planning no longer relies on manual item-by-item verification but is automatically arranged by the system based on load conditions and pending orders, ensuring stable operation of the production line while maintaining high efficiency.

Green production and resource optimization

As the industry increasingly emphasizes green production, intelligent inner liner bag-making machines also demonstrate positive effects in material saving and energy management. Reduced material waste means lower costs and a less burdensome environment; stable sealing results reduce product scrap rates, allowing for more rational use of resources at every stage.

Intelligent bag-making equipment drives high-quality industry development

In the context of increasingly fierce global market competition, companies must rely on more advanced technology and equipment to gain a greater advantage in the packaging industry chain. The Intelligent Liner Bag Making Machine's performance in stability, flexibility, traceability, and digitalization makes it a key force driving the industry towards high-quality development.

The role of emerging technologies

With the continuous penetration of technologies such as artificial intelligence, image recognition, and the Industrial Internet, future bag-making equipment will be more intelligent, bringing broader possibilities in handling complex materials, producing diverse bag types, and remote maintenance. Upgrading to this type of equipment will not only improve production efficiency for enterprises but also enhance their market competitiveness through higher-quality liner bags, accelerating the accumulation of brand value within the supply chain.

Conclusion

The emergence of the Intelligent Liner Bag Making Machine marks a new stage in the packaging equipment industry. Its increased production efficiency, enhanced quality stability, and intelligent management capabilities are propelling the entire packaging ecosystem towards a safer, more efficient, and greener direction. In today's strong transformation of the manufacturing industry, intelligent liner bag making machines have become an important choice for more and more companies moving towards high-end production, and the industry will usher in a more dynamic future driven by this technology.

RELATED PRODUCTS

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

English

English 中文简体

中文简体 русский

русский Español

Español